Sheet Metal Fmea

Sheet metal is formed cold.

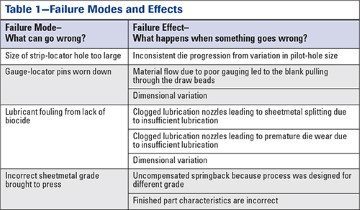

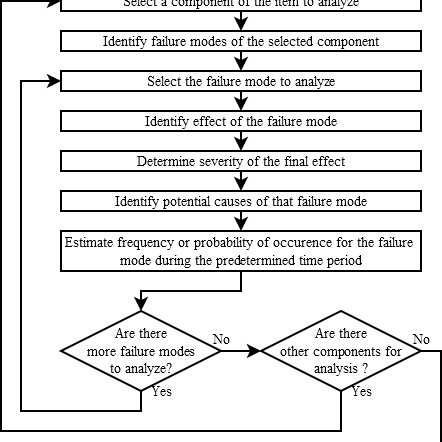

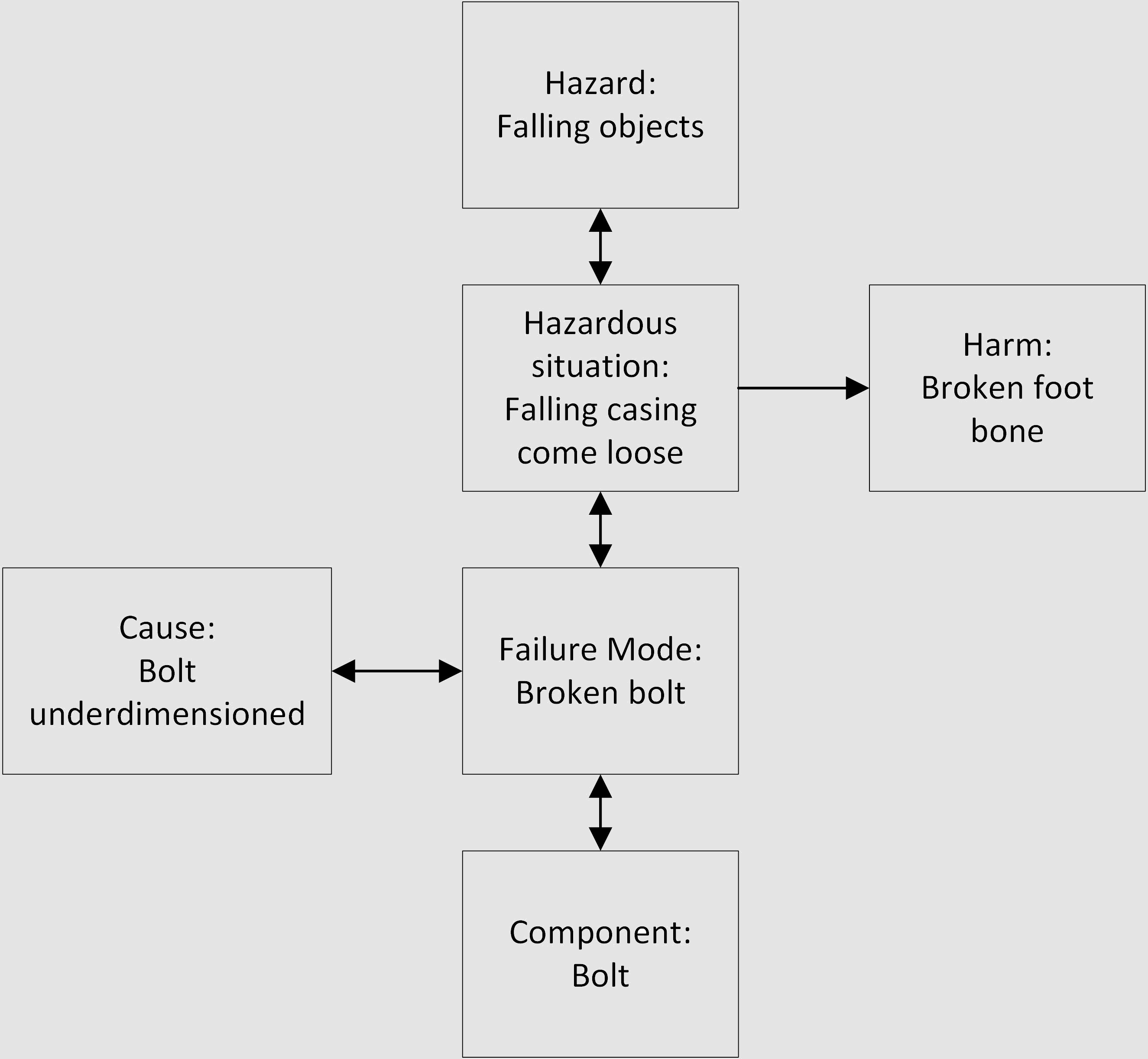

Sheet metal fmea. The die at the top is called a punch. The focus is on manufacturing related deficiencies with emphasis on improving the manufacturing process ensuring the product is built to design requirements in a safe manner with minimal downtime scrap and rework. This paper will give a brief view of rules and flow of fmea to apply it in sheet metal industry. Failure mode effect analysis fmea risk priority number rpn.

This paper will give a brief view of rules and flow of fmea to apply it in sheet metal industry. This is a commonly used manufacturing process that helps in manufacturing the parts for tons of known and unknown purposes. Sheet metal forming process is done on a press and the parts are formed in between two die. An fmea is analytical technique employed by a team as a means to assure that to extent possible potential failure mode and their causes have been consider and address.

Process fmea analysis is at the manufacturing assembly process level. Failure mode effect analysis fmea risk priority. Failure mode keywords. Sheet metal forming processes.

Click image to get our fmea failure mode and effects analysis worksheet free download available traditionally an engineering tool the fmea worksheet is also useful when assessing the risk of a lean.