Sheet Metal Fold Over Itselt

Sheet aluminium can be cut without the need for a guillotine or tin snips which tend to deform the metal.

Sheet metal fold over itselt. Similar to other metal forming processes bending changes the shape of the work piece while the volume of material will remain the same. Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape. Place the fracture line over the edge of a table and bend the overhang slightly downwards. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

This is done through the application of force on a workpiece. This creates the bent shape in the sheet metal. The force must exceed the material s yield strength to achieve a plastic deformation. Forge hammer or roll the metal.

How large of a bend you put in the metal depends on the application and fitment of the piece. Each model is made with superior design and includes handy sight holes to ensure proper depth alignment. When working with a brake press hems are always created in a two step process. Fold the sheet metal over itself.

Folding over the edge of a piece of sheet metal will give the metal instant structural integrity. 100 tonne press brakes nc controlled. Get a free quote today. By doing this metalsmiths are either creating the main form of the figure or making the area where the metal is folded more distinctive.

Whether you are an hvac or roofing pro malco offers you the right tool to get the job done. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Create a bend with acute angle tooling in the metal 30 is preferable but 45 will work for some circumstances. Bending is one of the most common sheet metal fabrication operations.

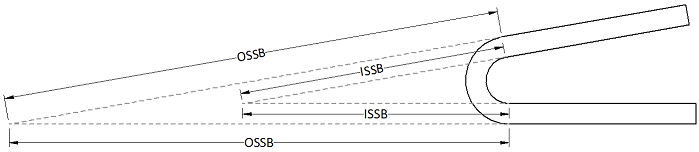

If you re just trying to strengthen a panel a broken edge as small as inch wide can make a big difference in the strength of the panel. Over 51 years of trusted quality service. In sheet metal hemming means to fold the metal back on itself. Malco s 12f 18f and 24f sheet metal folding tools offer a premium choice for bending and forming metal.

This weakens the aluminium and creates a fracture line. Sheet metal bending is the plastic deformation of the work over an axis creating a change in the part s geometry.