Sheet Metal Forming Nptel

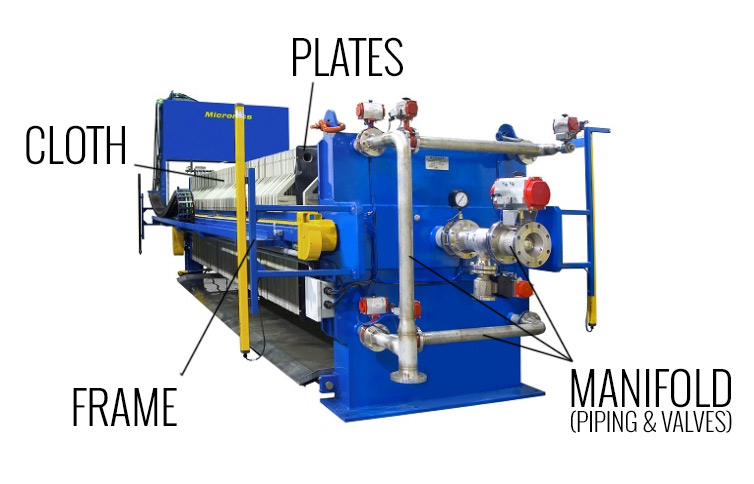

These are casting machining joining welding mechanical fastners epoxy etc and deformation processes.

Sheet metal forming nptel. Sheet metal forming operations. Sheet metal forming operations. Sheet metal operations ii. Bending of sheet metal quiz questions.

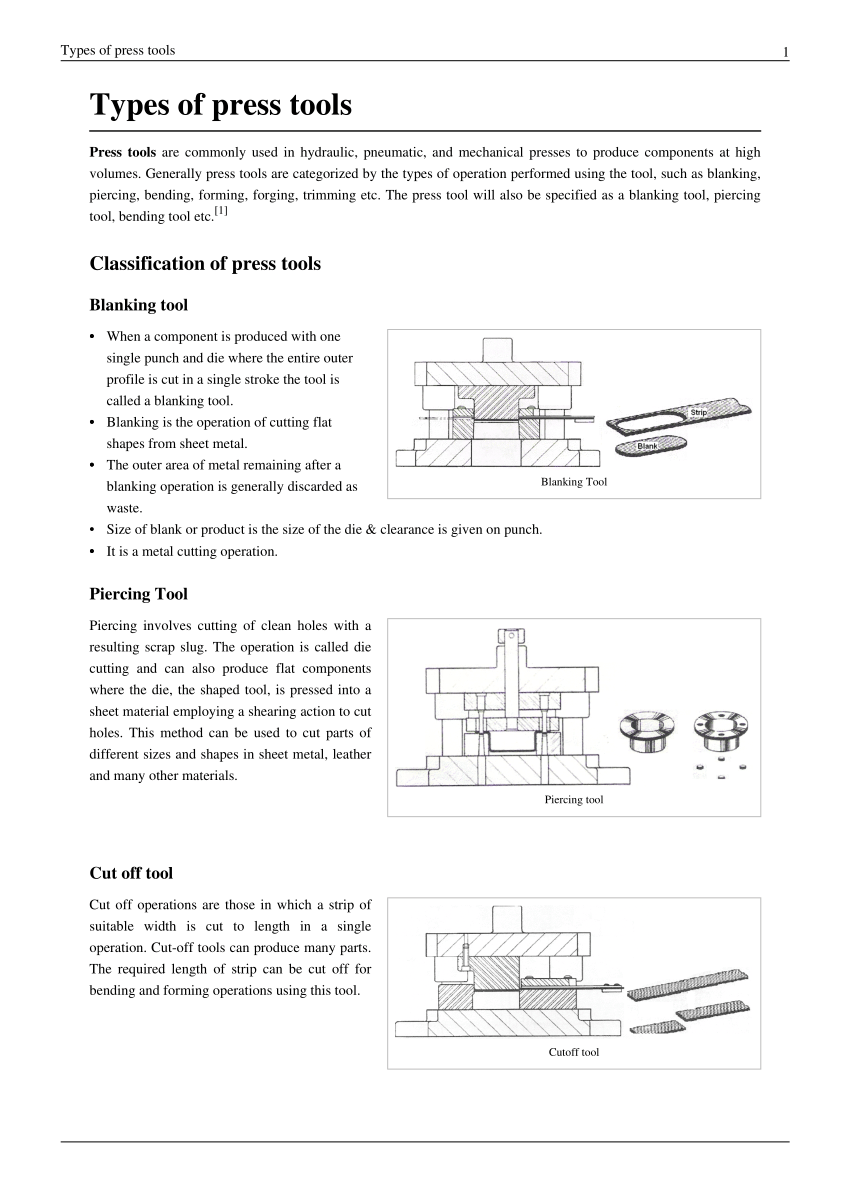

Sheet metal operations i. Classification of metal working processes. Mechanics of sheet metal forming 1. Sheet metal forming operations.

Understanding basic principles of metal forming and further being applied by engineers and metallurgists directly contribute towards improvement in production in the industries. Casting process exploit the fluidity of a metal in liquid state as it takes shape and solidifies in a mold. Heat transfer and thermomechanical processing. Cutting and related operations quiz questions.

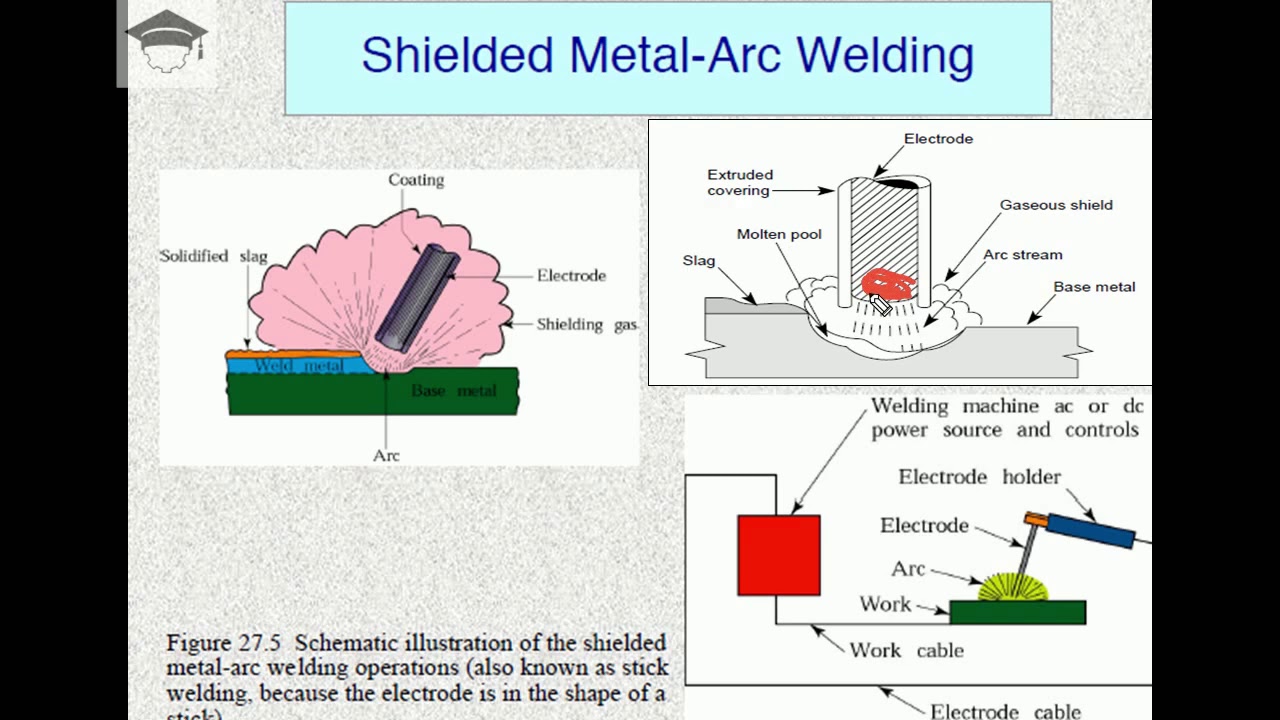

Fusion welding processes 1. Physics of welding and metal transfer. Behavior of materials. Bending of sheet metal.

Mechanics of bulk metal forming. The surface area to volume ratio of the starting metal is relatively high. Principles of metal forming technology. All other factors influencing sheet metal forming we should recall that a sheet metal forming operation can always be from the conceptual point of view divided in two stages.

Introduction to metal forming technology. Cutting and related operations quiz key. Sheet metal forming operations. Classification of basic sheet forming processes.

Sheet metal forming involves forming and cutting operations performed on metal sheets strips and coils. A first stage where the volume of the part is generated a second stage where the. Fusion welding processes 2. The concept of stress deformation and failure mechanics of metalworking and analysis of different metal working processes will be covered during the whole course.

Fundamentals of metal forming there are four basic production processes for producing desired shape of a product. Nptel provides e learning through online web and video courses various streams.