Sheet Metal Galling

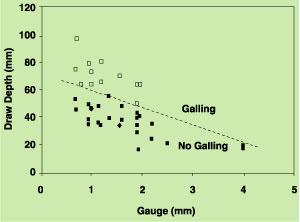

Therefore the results cannot be applied directly to sheet metal forming operations.

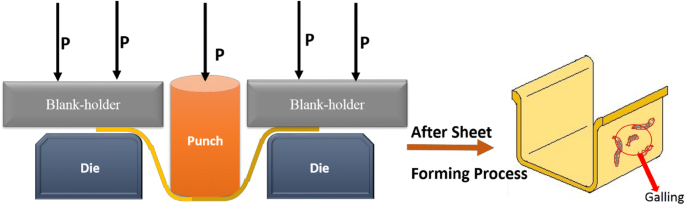

Sheet metal galling. Sheet metal stamping is one of many processes prone to galling a form of wear. The lubricity hardness and abrasion resistance of these pvd coatings reduces friction between the sheet metal and tool resulting in 8 to 40 times longer tool life more press up time and improved part quality. In sheet metal forming galling occurs in three phases. Iii the adhered lump on the tool becomes highly work hardened and it can cause scratches on the blank material.

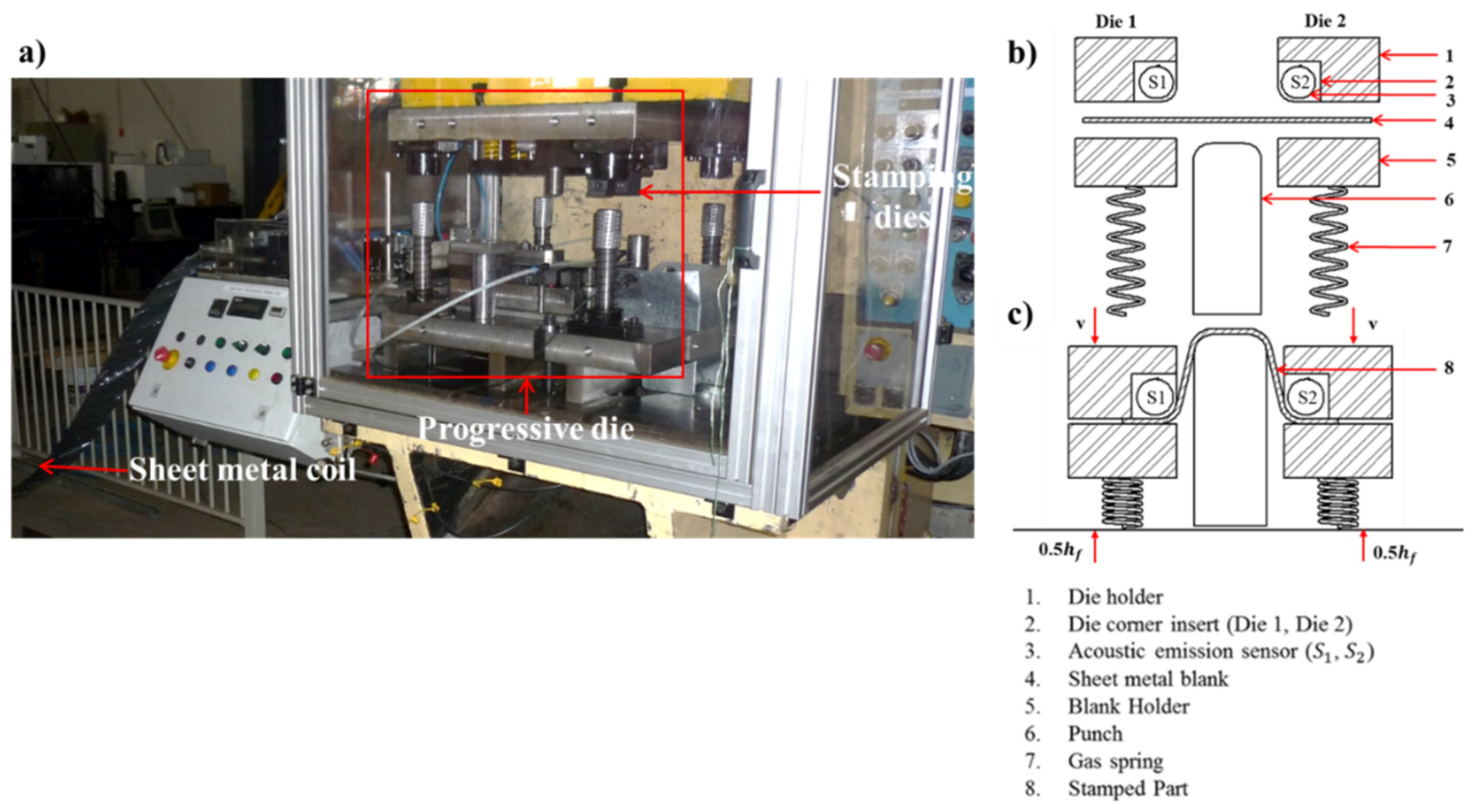

In abrasive galling the tool steel breaks down because of the abrasive nature of the material being formed or cut. These in turn cause higher die wear and galling. Galling occurs when metals with dissimilar hardness the die and the sheet metal come in contact at high speeds and pressures. Stamping also known as pressing is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape.

Galling is a common problem in sheet metal forming bearings and pistons in engines hydraulic cylinders air motors and many other industrial operations. Galling and die polishing will be a thing of the past with our high performance pvd coatings. Although various countermeasures have been adopted in production to prevent excessive wear associated with forming dp980 steel the stamping die tryout process has not been revised accordingly to ensure that the die surfaces in contact with sheet metal have been hardened and coated. Abrasive galling is similar to sanding wood with coarse sandpaper.

Stamping includes a variety of sheet metal forming manufacturing processes such as punching using a machine press or stamping press blanking embossing bending flanging and coining. The ball scratching test is extensively used to evaluate galling in sheet materials carlsson et al 2001b van der heide and schipper 2003. Galling begins at tool defects such as notches or scratches and eventually develops into hard protrusions on the tool surface. Galling is considered a unique form of wear on metal because it actually causes adhesion.

However in this test the plastic deformation of the sheet that occurs in stamping is ignored. Most other wear or friction formats involve metals coming into contact and eroding as a result but galling is different it actually causes metals to connect to one other instead creating a whole host of separate issues. In adhesive galling the metallurgical properties of the tool steel and the sheet metal are similar. I initiation of the lump on the tool due to the sliding contact at the sheet tool interface.

-min.jpg)