Sheet Metal Gap No Welding

To avoid rework follow the measure twice cut once rule.

Sheet metal gap no welding. Place the welding tip wire at the gap and tack weld several small spots spacing them evenly apart. While replacing body panels overheating and warping thin sheet metal is common. Welding 18 and 20 ga sheet metal. Most textbooks tell you to butt thin sheetmetal together then tack and weld.

Offered independently and as a complete solution all works are undertaken to the highest quality with our iso 9001 certification. There are 2 basic methods to mig welding large gaps the first is to use filler metal to help cover the gap that is cut to size to fill the gap and help make the weld a smoother process. If so you can use 035 mig wire and hammer weld the panels then file and metal finish. Caron first addresses why you should avoid g.

Welding thin metal demands tight fit up. Now a word about that money that i mentioned specifically those nickels and dimes. You are tig welding theses panels. Fit up and joint design.

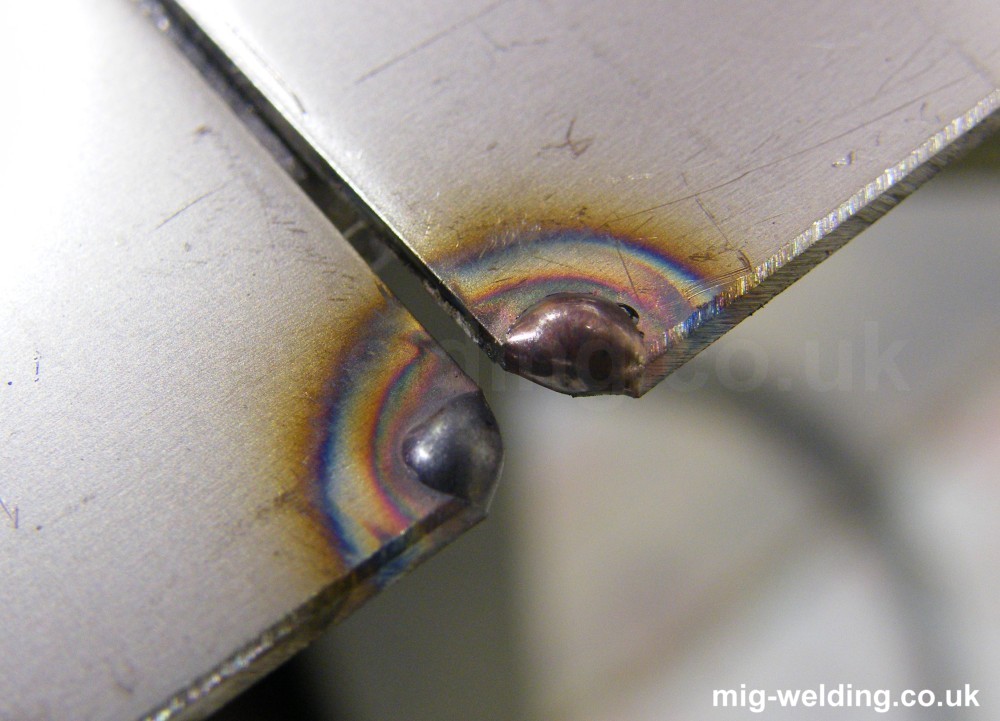

If the parts fail to touch each other for even 1 16 inch you have created a hole that invites burn through and a gap that can t absorb the heat. You want no gap. In 20 to 22 gage sheet metal your fit up gap for mig butt welding should be no less than the thickness of an unworn dime but it doesn t hurt to be stingy with your money and generous with your fit up gap. When i was taught gas welding at a coommunity college the instructor insisted that all metal 1 8 or less should have a gap of the metal thickness between them.

Then you tack and weld. A gas welding technique question. The second is to do a root pass to fill the bottom of the gap and using stringer beads to fill the gap. Then tack between the two previous tacks.

Including in house cutting forming welding machining and finishing. Tack in a few places apart from each other and wait until the panel is cool to the touch. Imagine a butt weld on 20 to 24 gauge metal. He claimed much reduced distortion as a result.