Sheet Metal Guillotine Blade Angle

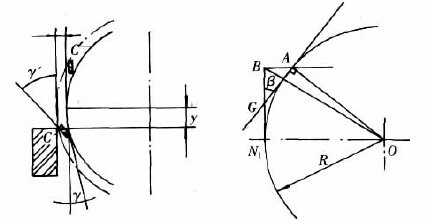

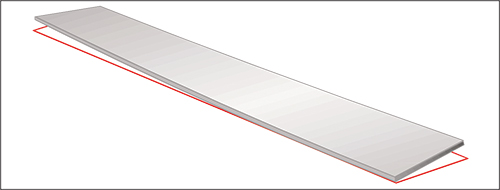

Blade angle and clearance calculation depend on the standard material.

Sheet metal guillotine blade angle. Sheet metal and plate shearing machines are used in many fabricating and sheet metal operations. For example a 16 mm thick plate should be cut with a 0 04 16 0 64 mm blade clearance. Hand guillotine shear hand plate shear. Not for sheet metal wood leather rubber or roofing materials.

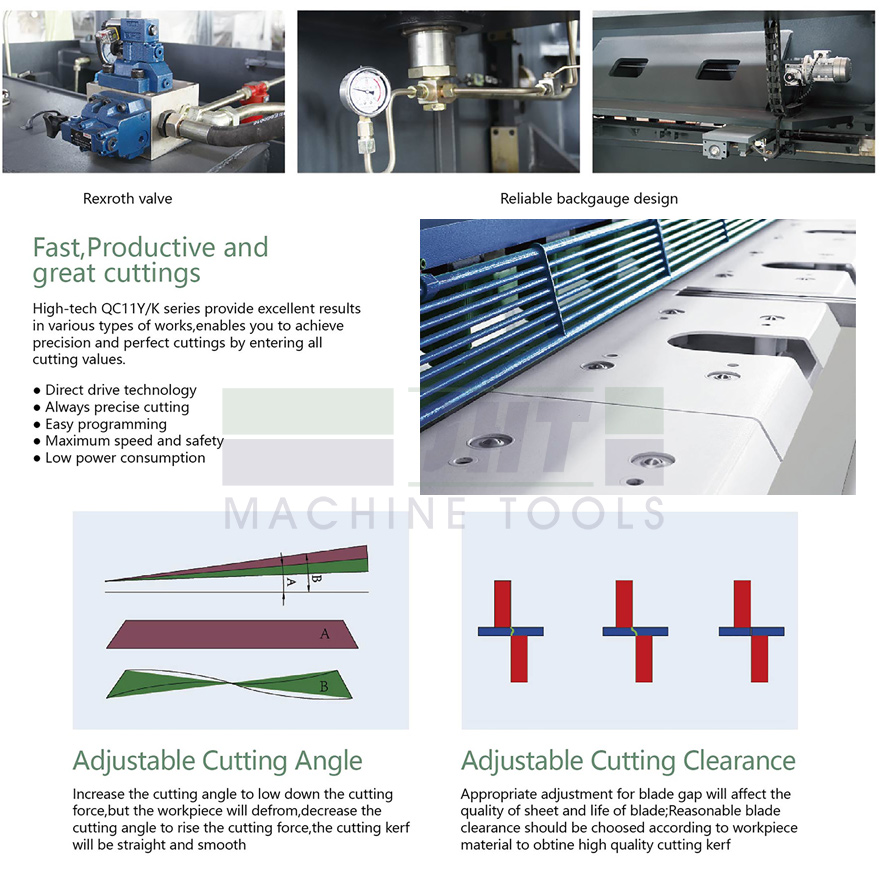

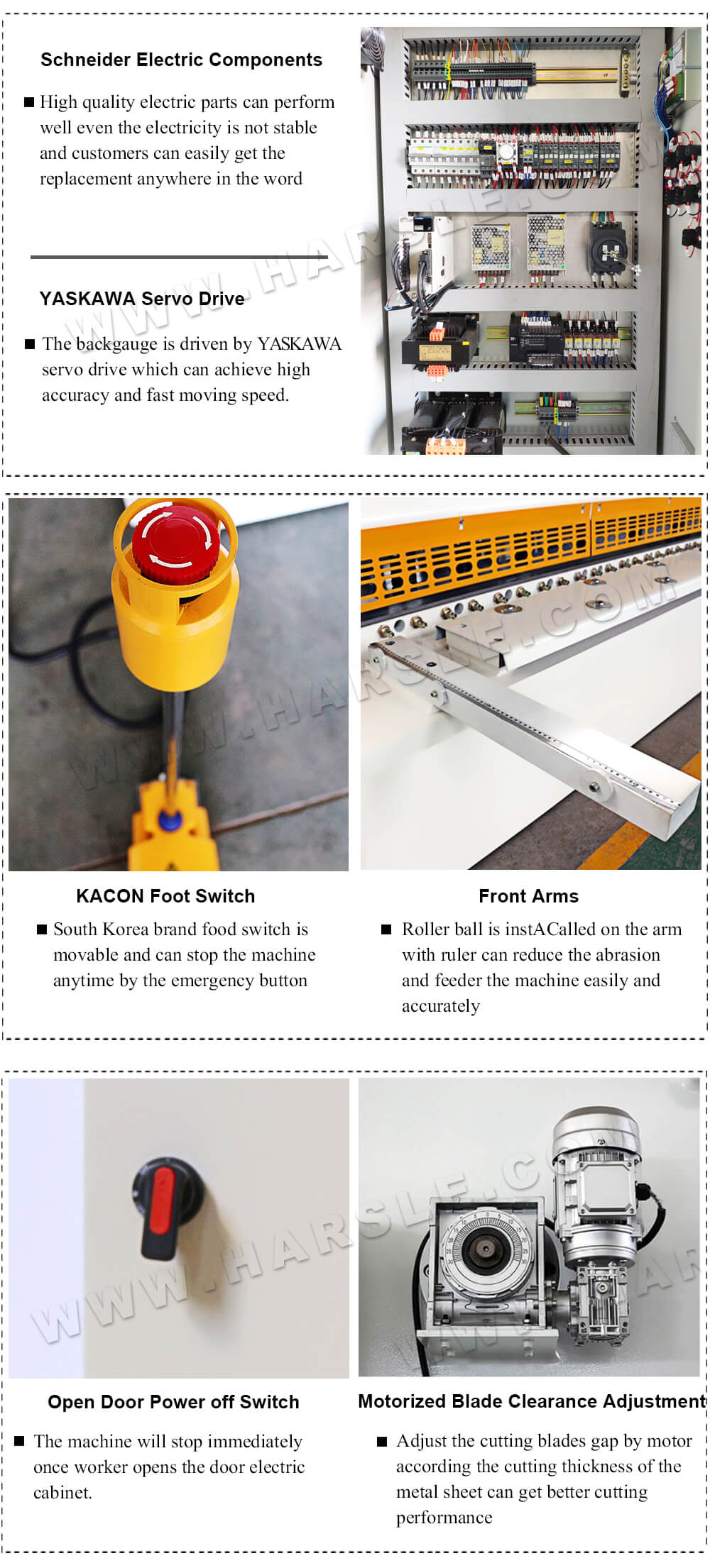

On the cnc hgm model the blade gap clearance rake angle cutting length and backgauge positioning are automatically adjusted after programming the dnc with the data of the plate to be cut. In imperial units a 1 2 plate should be cut at 0 06 x0 5 0 03 blade clearance. Cut through hundreds of sheets at a time. 2500 mm cutting angle.

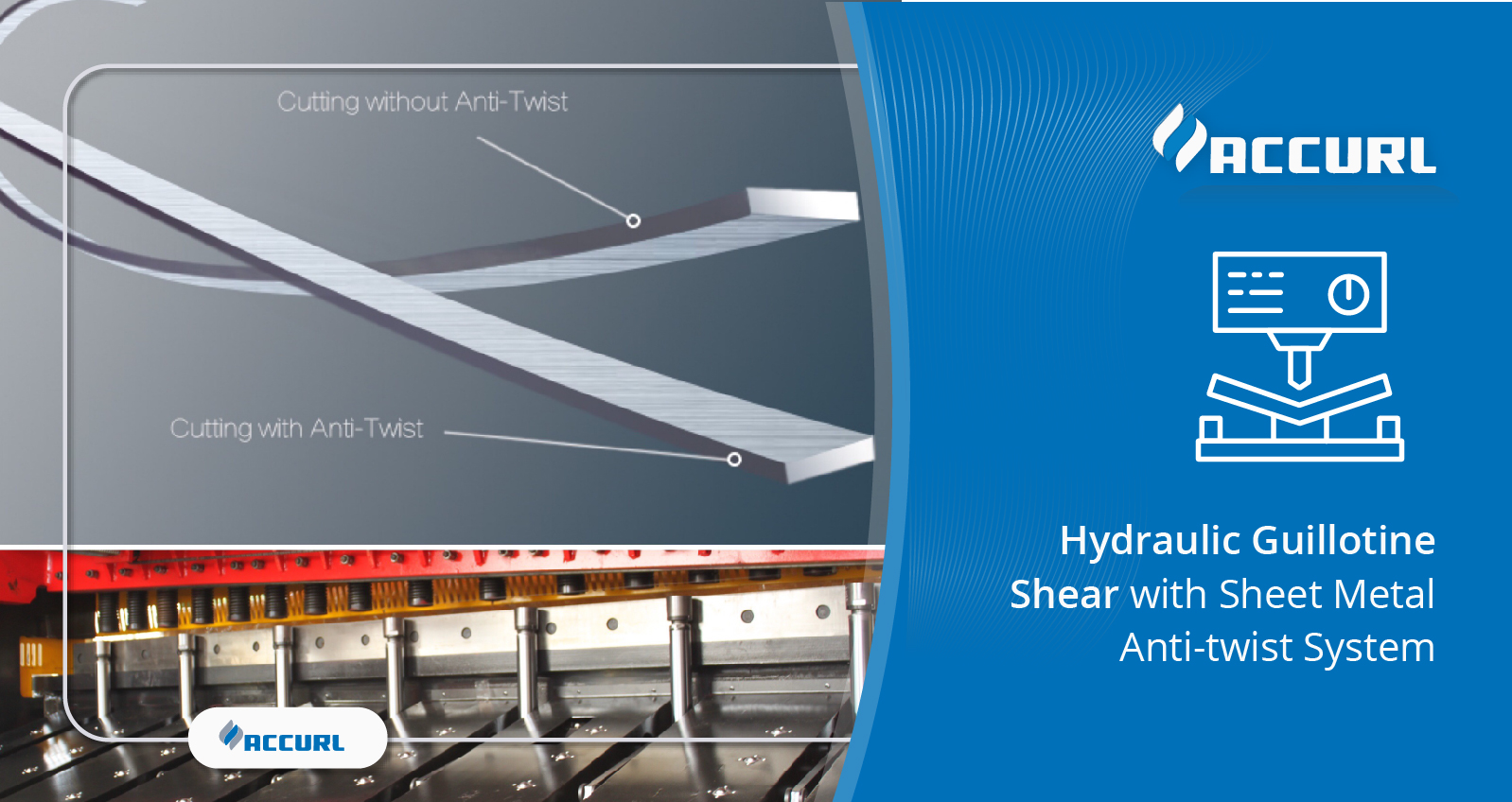

Adjustable reach of stands. The amount of energy used is still the same. In the diamond guillotine shears the cylinders are perfectly in line with the blade holder tilted at an angle specifically designed for a capacity of sheet metal trimming up to half its thickness and less wear of both seals and cylinders. The moving blade may also be inclined 0 5 to 2 5 called the rake angle to keep the.

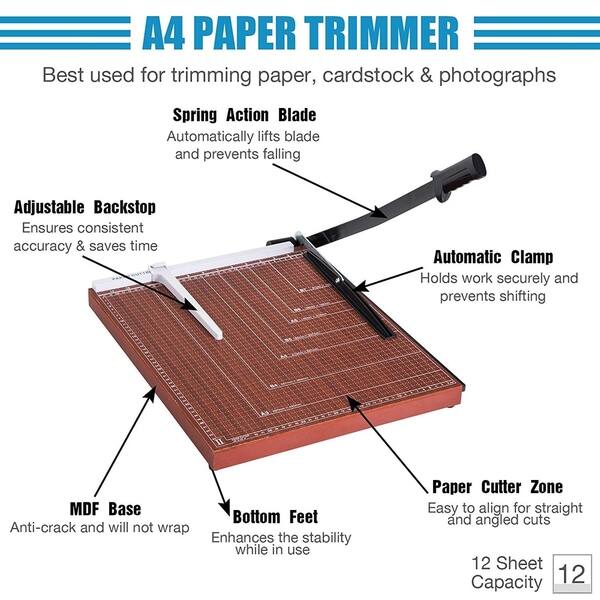

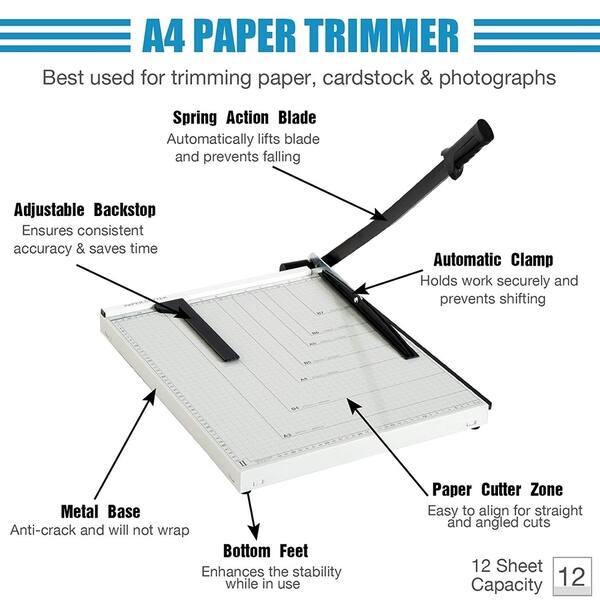

Axe and status uk supplier and distributor of durma cnc machine tools sheet metal machinery and cnc fiber lasers. The hold down clamp securely holds the paper in place while roller guides control the blade for easier cutting of large capacities. 1 33 grad cutting angle. One blade one the shearing machine does the reciprocating linear motion relative to the other blade to realize sheet metal cutting purpose.

0 6 mm maximum thickness of cut sheet rm 450 mpa. Blade ram is not perfectly vertical but tilted poiting towards the back to facilitate piece separation. 4 750 mm main drive motor. Guillotine machines require a gibbing system to keep the blade beams in the proper position as they pass each other.

Metalwork guillotine shearing machine is designed by ansys software which can ensure the reliability and precision of the machine. 200 mm adjustment range of the rear bumper. Uses a drive system to power the moving blade down and in a position almost parallel to the fixed blade during the entire stroke. We recommend setting the blade clearance around 10 of the metal sheet thickness.

Sheet capacity is based on standard 20 lb. Minimum thickness of cut sheet. 4 mm maximum width of cut sheet. This is one of the quickest and easiest ways to manufacture sheet metal for use.

Setting the blade on an angle decreases the amount of force required but increases the stroke. The guillotine blade uses kinetic energy to cut the sheet metal at the appropriate angles sides and force requirement.