Sheet Metal How Expensive Is A Hhem

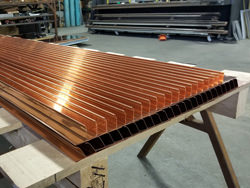

Production plants for conventional die hemming are very expensive but the cycle times are very low.

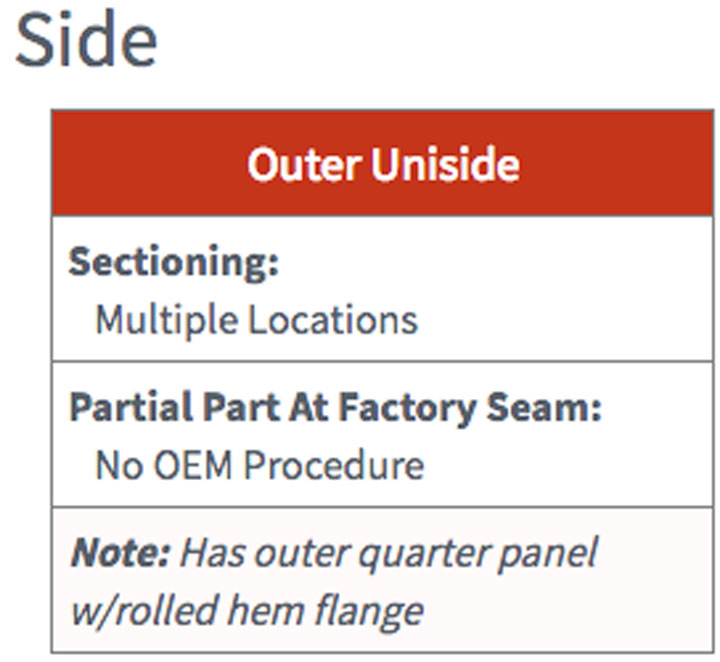

Sheet metal how expensive is a hhem. Sheet metal is metal formed by an industrial process into thin flat pieces. With the right tools however manufacturing companies can hem sheet metal by bending and rolling the edge over and onto itself. High gauge sheet metal is thicker than low gauge sheet metal which can make it difficult to manipulate using processes like hemming. As a design element the hem creates the appearance of greater thickness without adding much weight.

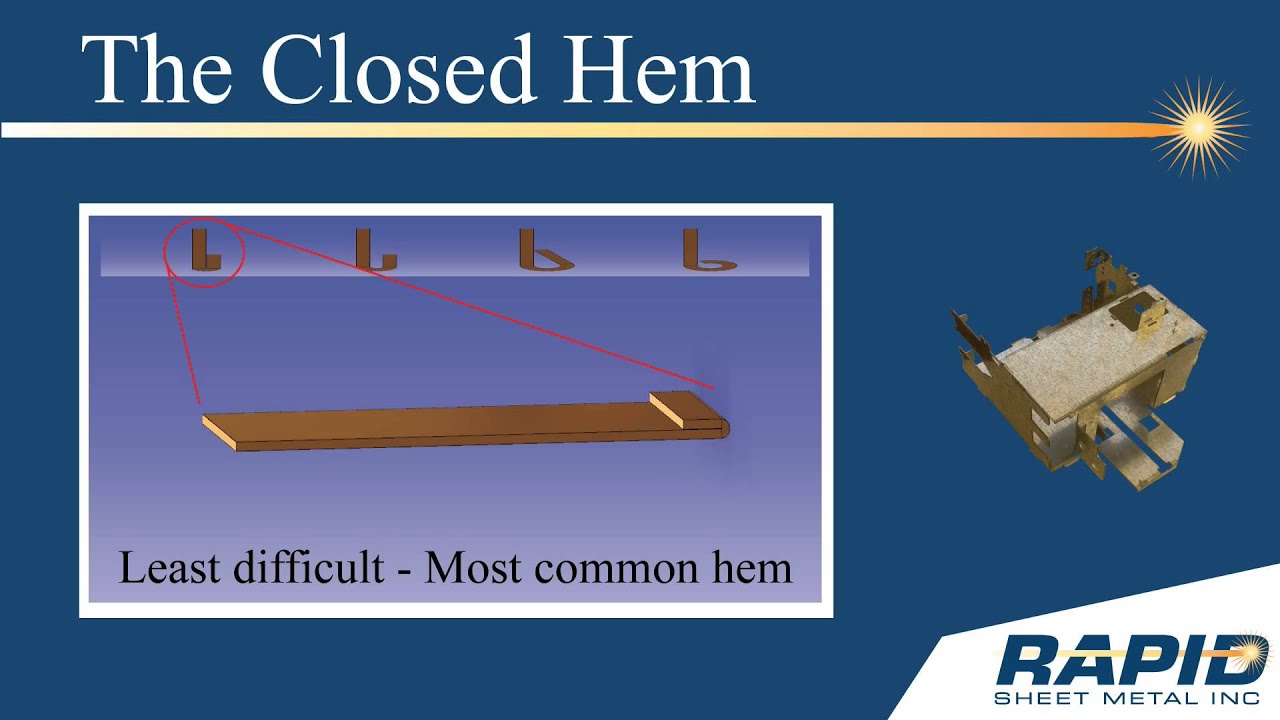

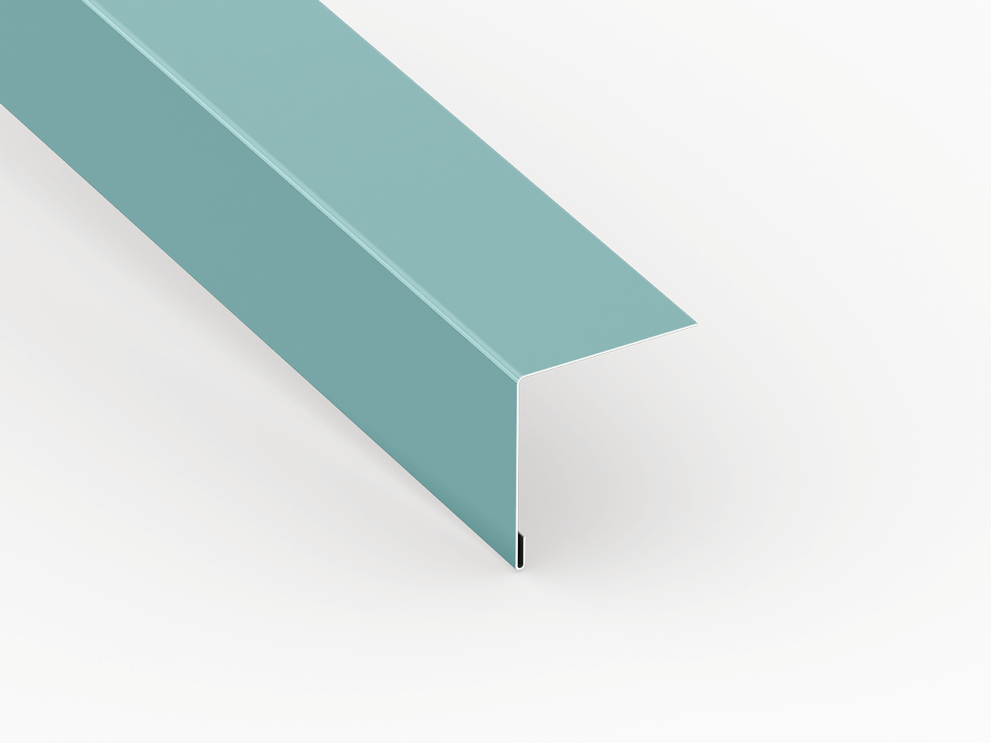

Hemming is a metalworking process where a sheet metal edge is mechanically bent to fit an uneven surface or simply roll over onto itself. Create a bend with acute angle tooling in the metal 30 is preferable but 45 will work for some circumstances. In sheet metal hemming means to fold the metal back on itself. It creates a very smooth edge and can hide the raw edge of the part.

Hems can be useful as a way to stiffen a sheet metal panel. Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes countless everyday objects are fabricated from sheet metal. And while hems or seams reinforce a sheet metal edge their main purpose is to improve appearance by hiding burrs and rough edges on metal back splashes and other sheet metal installations. Hems are commonly used to reinforce an edge hide burrs and rough edges and improve appearance.

For pricing and availability. Hems have drawbacks however. To model hems in sheet metal i m. Bends in sheet metal are manufactured using sheet metal brakes.

Hemming is the process in which the edge is rolled flush to itself while a seam joins the edges of two materials. When designing parts for laser cutting one should not make holes smaller than the thickness of the material. Roll hemming operation can also be divided into several pre hemming and final hemming process steps. Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself.

Hillman 24 in x 24 in cold rolled steel solid sheet metal. When working with a brake press hems are always created in a two step process. A 1 degree tolerance on all bend angles. Thicknesses can vary significantly.

This is sometimes a way to add durability to painted parts. M d 24 in x 3 ft aluminum sheet metal. Seems to work but wondering if there s a better practice recommended. Extremely thin sheets are considered foil or leaf and pieces thicker than 6 mm 0 25 in are considered.

The gauge of course refers to the thickness of sheet metal. Sheet metal parts with a minimum of 0 9mm to 20mm in thickness can be manufactured.