Sheet Metal How Thick For Seal Weld

Andy gives helpful insights and tips to mig weld thin sheet metal.

Sheet metal how thick for seal weld. What thickness or gauge is standard automotive sheetmetal on american vehicles such as a door skin or fender skin. I keep blowing through my thin sheet. Tig welding sheet metal. Try going for a wire of 023 inches when welding sheet metal.

This is why production body shops swear by them. Spot welding is usually used to join a panel of overlapping sheet metal parts that are usually 3mm thick. The ration of thickness should not exceed 3 1mm. Lap welds are used when quick results are needed.

Forget the larger 1 8 inch tungsten electrode and use a smaller one. When welding mild steel a good rule of thumb is to set the amperage level at 1 amp for every 0 001 of thickness. I m practicing up on my mig and am trying to determine settings using er70 6s and c25. Metal thickness amperage settings.

Stick welding sheet metal with 6013 rods. For sheet metal i use ine welding wire and it is just as good as their flux cored wire if you want you can grab one here. To weld sheet metal with solid wires use electrode positive ep or reverse polarity. A lap weld is much easier than a butt weld but doesn t seal correctly and will promote moisture from the back side.

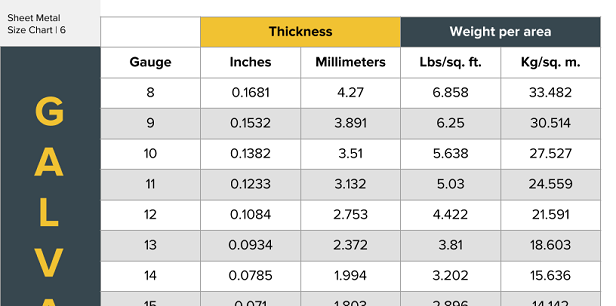

Short bursts or tacks will help. Butt weld vs lap weld. This is because the strength of the joints depends on the number and size of the weld. The tables in my texts and on the machine reference gauge.

Andy fogarty demonstrates how to weld thin metal to thick. While wire feed welding sheet metal go for short bursts of welding instead of a going on a long bead. So if you are welding 12 gauge mild steel with a thickness of 0 100 you would set the machine at 100 amps. Thanks for any info.

This is the thinnest sheet metal i have ever welded using this process.