Sheet Metal Stamping Dies Pdf

All other factors influencing sheet metal forming we should recall that a sheet metal forming operation can always be from the conceptual point of view.

Sheet metal stamping dies pdf. These designs are then translated into stamping dies by skilled craftsmen known as diemakers. In bending and embossing of sheet metal the female die is replaced with rubber pad rubber pad forming rpf is a metalworking process where sheet metal is pressed between a die and a rubber block made of polyurethane. Female die male die punch post metal sheet blank holder ring on cushion compressible cushion sheet metal stamping drawing car industry 90million cars and commercial vehicles produced worldwide in 2014. Like molds dies are generally customized to the item they are used to create.

Once these stamping dies are mounted into presses sheet metal is fed to them. Typically a dieface contains local elements sausages designed to. Different types of dies. Hydro forming cheap tooling no net.

At normal temperature a metal or non metal sheet is pressed on a stamping press machine by a stamping die to cause separation or plastic deformation thereby obtaining parts having a certain shape size and performance. They are commonly developed using computer aided design cad software and analytical programs to create and prove out highly accurate unambiguous designs. Basic knowledge of metal stamping process. Stamping auto body panels 3 to 5 dies each.

These dies do not control metal flow and cannot prevent the metal from wrinkling or buckling. Solid form dead hit dies also called crash forming dies deform the metal using only a punch and cavity. Die entry line stamping direction blankholder other run offs components. Cutting clearances between the punch and die are closely defined and specified.

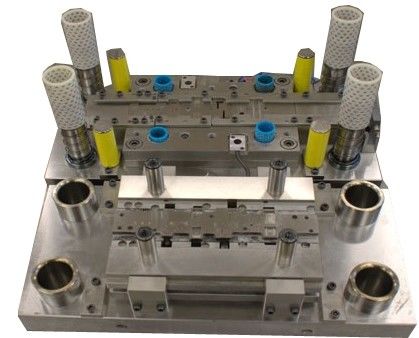

The definition of stamping. Under pressure the rubber and sheet metal are driven into the die and conform to its shape forming the part. Sheet metal stamping stamping presses and stamping dies are tools used to produce high volume sheet metal parts. Products made with dies range from simple paper clips to complex pieces used in advanced technology.

These parts achieve their shape through the effects of the die tooling. They are used to form simple parts such as brackets and braces made from thick stiff metals that are more wrinkle resistant than thinner metals. Normal metal stamping processes involve driving a sharpened tool steel punch through the sheet or strip material and into a die cavity where the slug or scrap is ejected. 1 1 metal stamping process characteristics and applications.

And the process produces a very predictable edge condition on the finished part. In this article i will be exploring the 5 types of dies used in sheet metal operations at respective stages and strokes. 20can pdf deep drawing of drinks cans. Stamping dies are the tools that shape and cut sheet metal parts.