Sheet Of Metal Passing Through Rollers Is Stronger Why

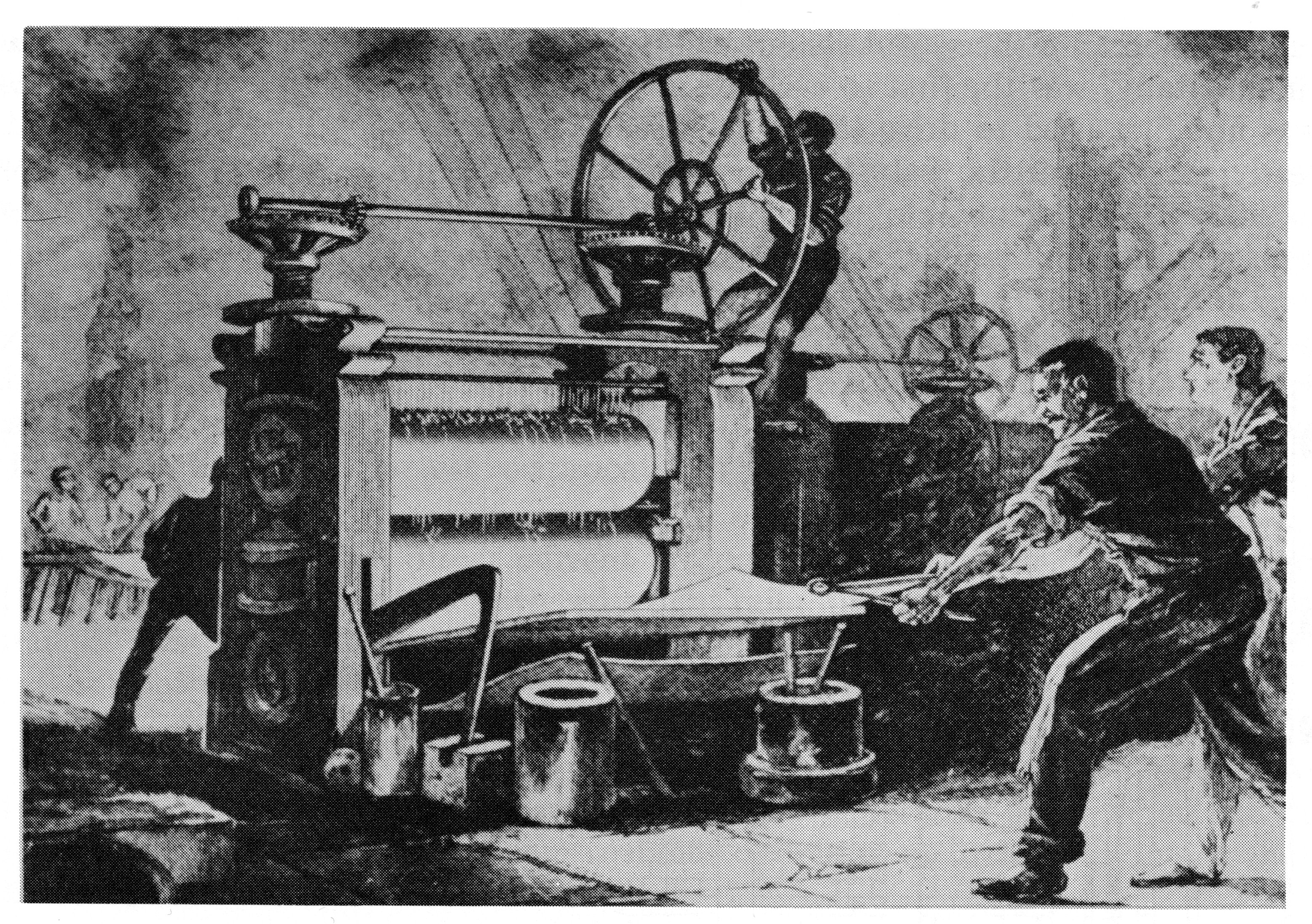

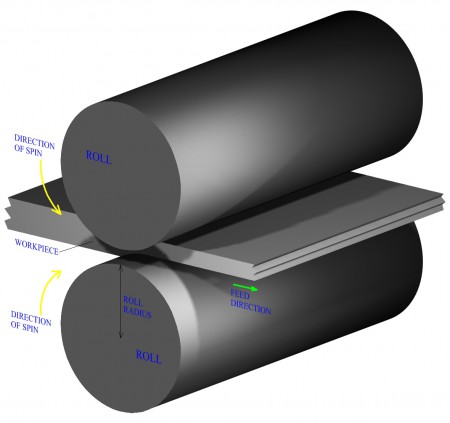

In metalworking rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform.

Sheet of metal passing through rollers is stronger why. This forces the material to pass through extreme angles to erase memory caused by trapped internal stresses. In this tech guide we re going to cover some of the ways you can modify a piece of sheet metal. You can tell how far apart the rollers need to be by passing your piece of sheet metal through the gap until it just starts to feel like the metal is about to get stuck then remove your items and turn the handle about a quarter turn so the rollers are tighter. Sheet metal is metal formed by an industrial process into thin flat pieces.

The gap between the rolls is set independently on a leveler s entry and exit. To level deeply nest the entry rolls. With hardened rollers and precision machined gears these rolling mills stand up to heavy use. The truth is that sheet metal can actually be very strong once we modify and strengthen it.

The sample is pressed and advanced through the rollers because friction pulls it into place as the rollers are turned. The concept is similar to the rolling of dough rolling is classified according to the temperature of the metal rolled. Knowing techniques for how to roll sheet metal edges and create grooves in a panel are important for fabricating new body panels on a restoration project. The first thing you need to do is to turn the handles at the top of your rolling mill to open up the gap between the two rollers.

A very basic roller straightener for metal banding strapping and wire. After several passes through the mill you may need to anneal your metal to soften it and. X 16ga single phase model esr 1650 1t. It s also called the plunge a technique for removing strip memory see figure 4.

This is as basic as c. Basic roller straightener for light gauge metal. If the temperature of the metal is above its recrystallization temperature then the process is. Thicknesses can vary significantly.

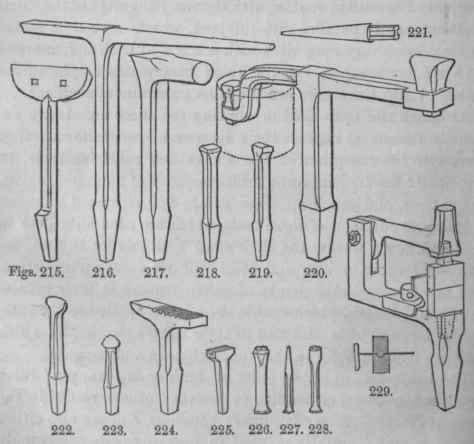

Feeding the metal strap or wire from one end and pulling it through all the rollers to the other end will make the material a lot flatter and straighter. They re often used to compress sheets to an uncommon gauge size convert scrap metal into sheets or wire or create different thicknesses in a single piece of metal without welding multiple pieces together. It runs direct drive from the to. In order to understand the microscopic effects of metal passing between moving surfaces we should first describe what happens when metal is squeezed between two unmoving surfaces.

A leveler uses. No bearings chains or sprockets. Jet electric sheet metal slip roller 50in.