Sheet Pile Wall Flexible Or Rigid

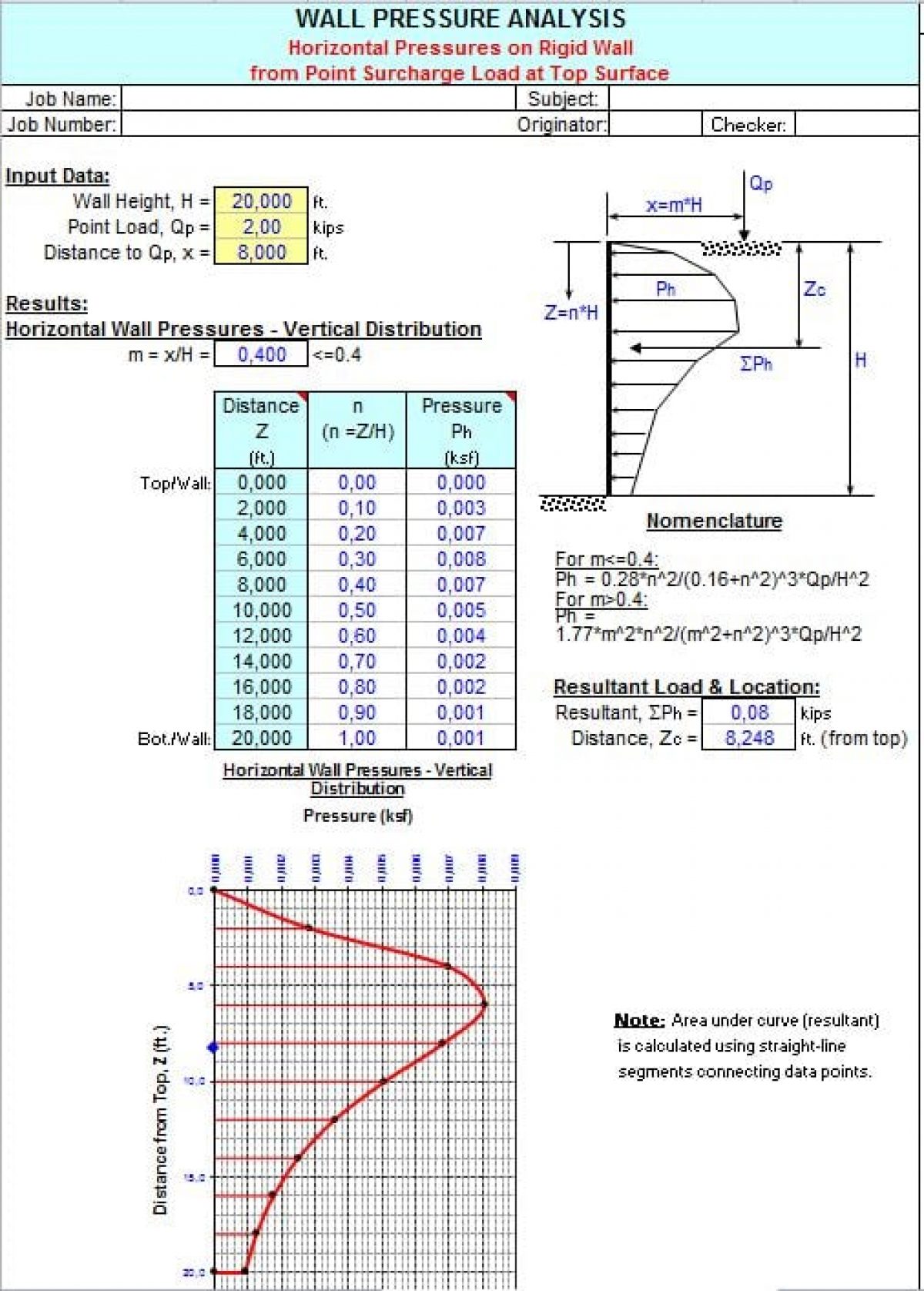

Penetrating sand and clay special cases anchored sheet piles design methods for sheet piles.

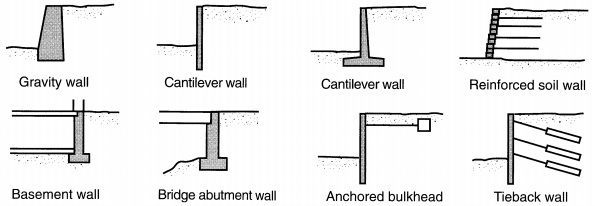

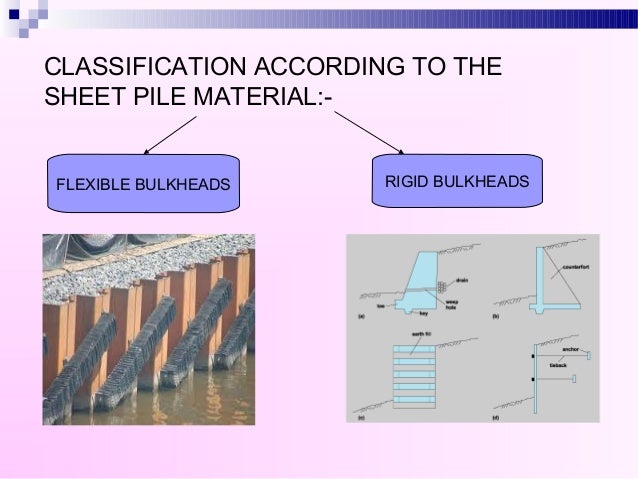

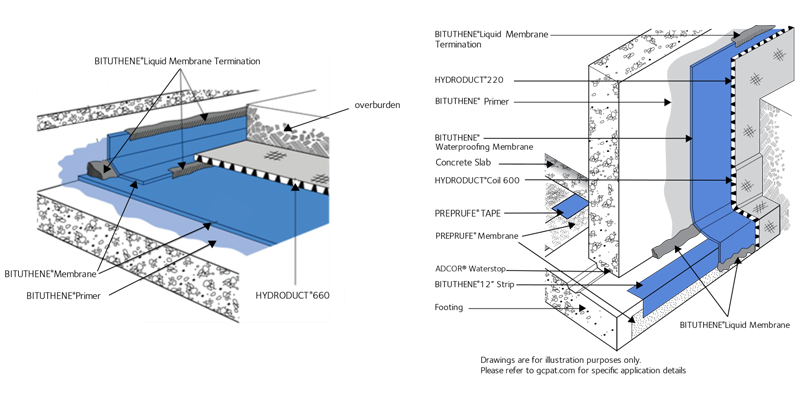

Sheet pile wall flexible or rigid. Provides higher resistance to driving stresses. While in the case of the cantilever wall of this type fig 4 the only source of stability is penetration into the soil below penetration and anchorage together contribute to the stability of anchored bulkheads fig 5. The most common materials for seawalls and bulkheads are steel concrete and timber. When a flexible bulkhead usually made of steel piles deflects and bends under the effect of a lateral force.

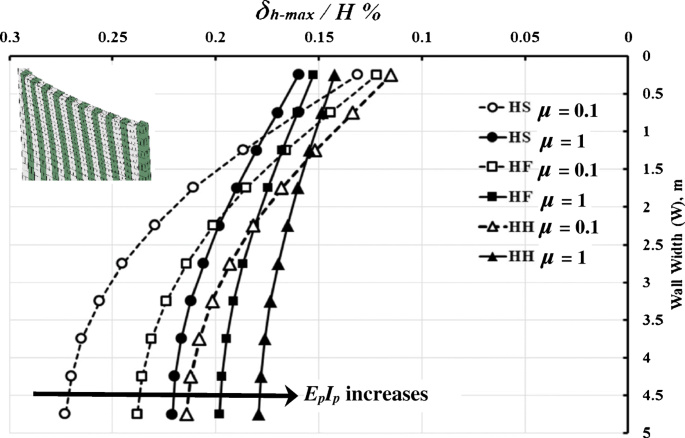

Tight installation tolerances are not a major concern mainly for temporary walls sheet pile are quite short leaning is not a predictable issue soil layers are not too compact. Built for superior impact resistance palladium rigid sheet keeps your walls protected and looking pristine for years to come. Sheet pile walls are retaining walls constructed to retain earth water or any other fill material. Can be made of steel plastics wood pre cast concrete.

Flexible rigid retaining wall systems design workshop 1 2 ceus we can offer our courses in new locations or customer prefered locations. Its also stability depends upon the formation of enough lateral resistance of soil adjacent to the embedded length of the bulkhead and upon the anchor rods. Permanent sheet piles remain in the ground and serve as permanent retaining structures such as levee strengthening retaining walls breakwaters bulkheads and environmental barrier walls. These walls are thinner in section as compared to rigid retaining walls sheet piles may be of timber reinforced concrete or steel.

Is of an overall lighter weight. The advantages of using steel sheet piling. Palladium rigid sheet wall protection is our most popular product. Sheet piles are one of the most common types of earth retention structures.

Heights 6 m if used with anchors. In addition to these traditional applications of sheet piling steel sheet piles are also used to take combined vertical and lateral loading for bridge abutments and underground parking garage projects. Sheet pile walls are driven into the ground and are composed of a variety of material including steel vinyl aluminum fiberglass or wood planks. It can be suitable when.

Hence it is quite fast and cheap. Steel piles can be driven into the foundation without extensive excavation. For a quick estimate the material is usually driven 1 3 above ground 2 3 below ground but this may be altered depending on the environment. Each sheet pile is threaded and driven directly to its final depth.

The foremost example of this category is the sheet pile wall which is too thin whether in steel reinforced concrete or timber for any stability to be derived from its self weight. The concept is very simple. Steel sheet piling is the most widely used bulkhead material. According to the sheet pile material a bulkhead may be classified as flexible or rigid.