Sheet Pile Wall Profiles

H2407 is a custom metal roll forming expert who can roll almost unlimited numbers of profiles in a variety of metals sheet pile manufacturers.

Sheet pile wall profiles. The interlocking systems devised for timber or concrete sheet piling have been based on the tongue and groove concept. It needs to be the highly durable as a retaining wall since loads have to be transferred vertically and horizontally. The segments are typically made of steel or another metal. Many wood sheet pile walls follow the navy wall design concept where loads are transferred to round timber master piles and standard dimensional lumber is used for the sheeting.

Sheet piles are retaining wall elements consisting of a structural section with a vertical interlocking system enabling the construction of a continuous wall. This type of h3607 pile should be restricted to short to medium wall height only for temporary structures. Sheet pile walls are widely used for both large and small waterfront structures ranging from small pleasure boat launching facilities to large dock structures where ocean going ships can take on or unload cargo. Z piles are the most common type of sheet pile in north america and can be used in a wide variety of applications.

In piling hot rolled steel sheet pile and cold formed steel sheet pile are two primary methods of manufacturing sheet pile. Straight web sheet piles. Retaining walls cofferdams parking garages environmental barrier walls and bulkhead walls for ports are just a few of their varied uses. Non ferrous sheet piles.

Sheet pile wall types construction methods advantages and disadvantages are described in this article. Steel sheet piles are used for both temporary and permanent retaining walls. The wood pile wall can be made up of wooden boards with independent or tenon grooves interlocked. As an enclosure wall it has to guarantee complete seal.

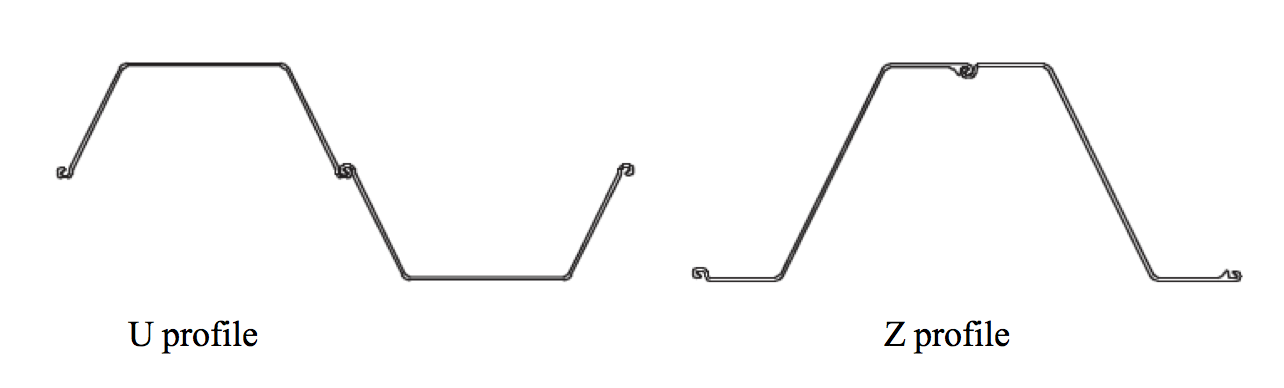

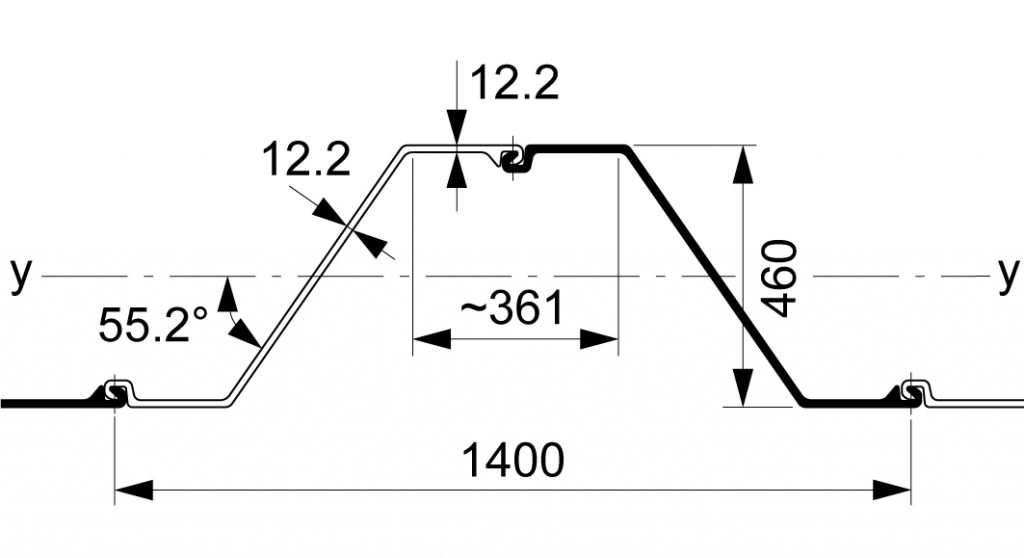

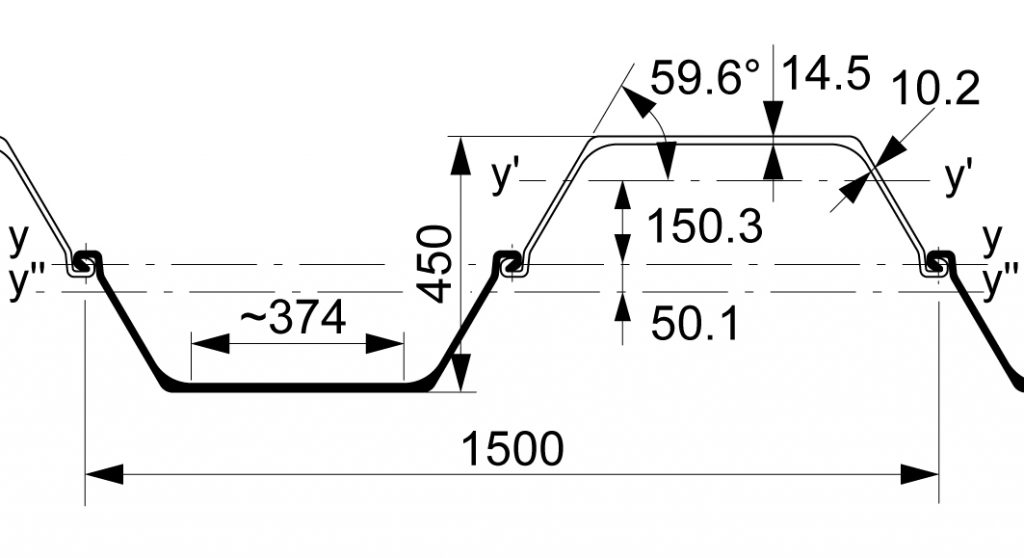

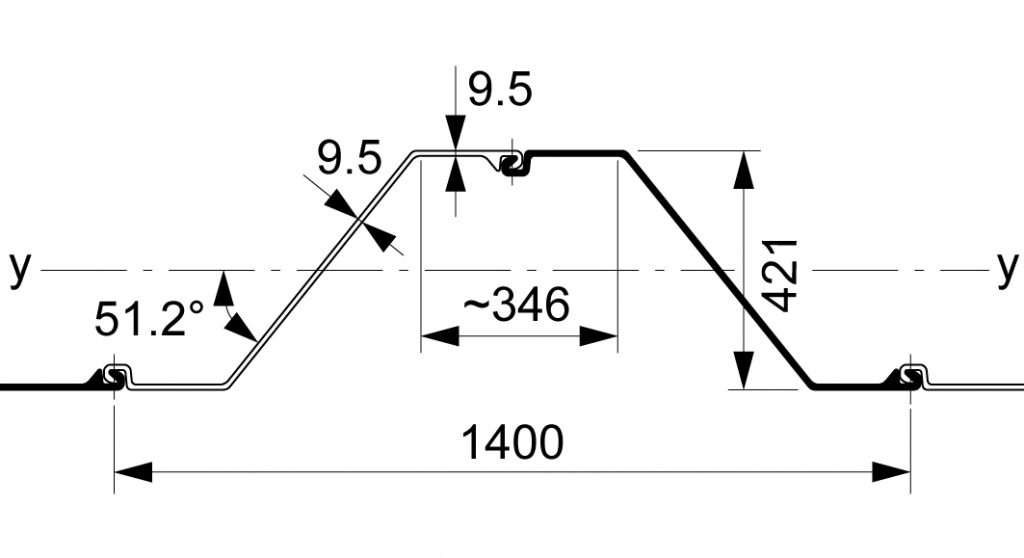

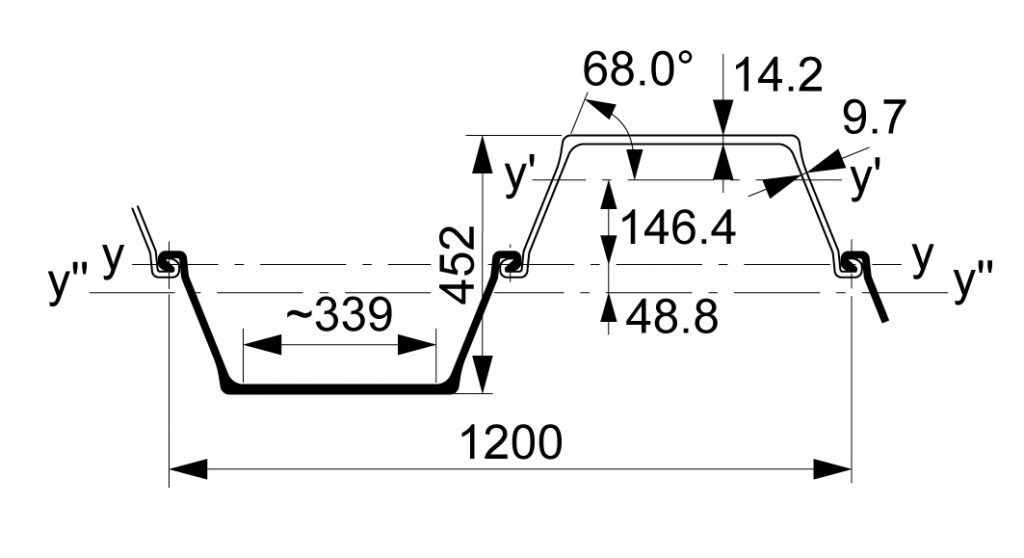

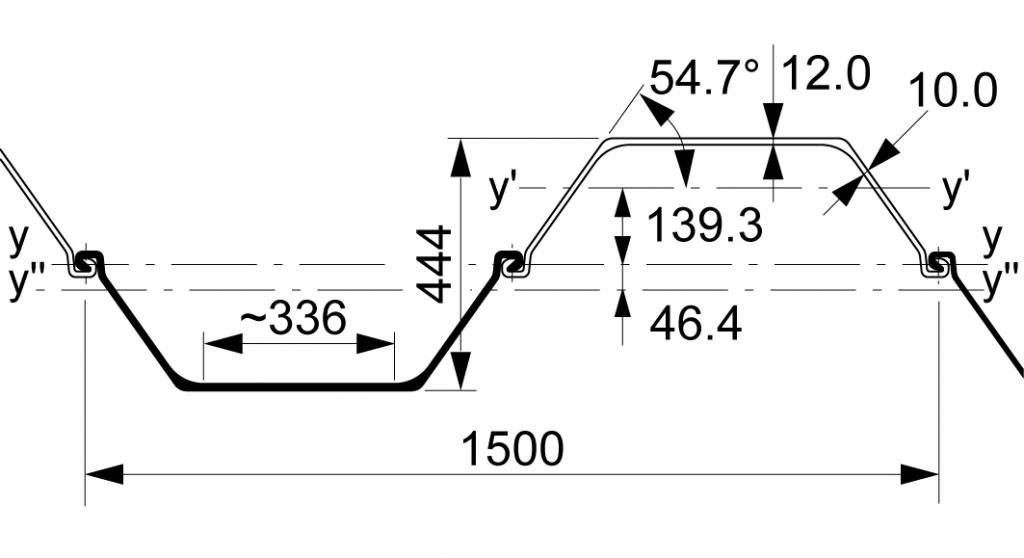

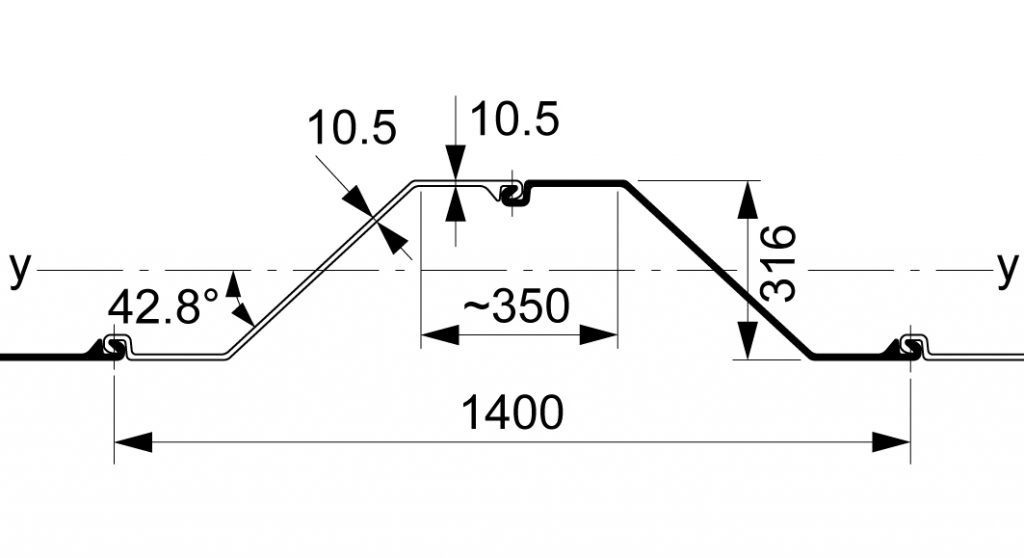

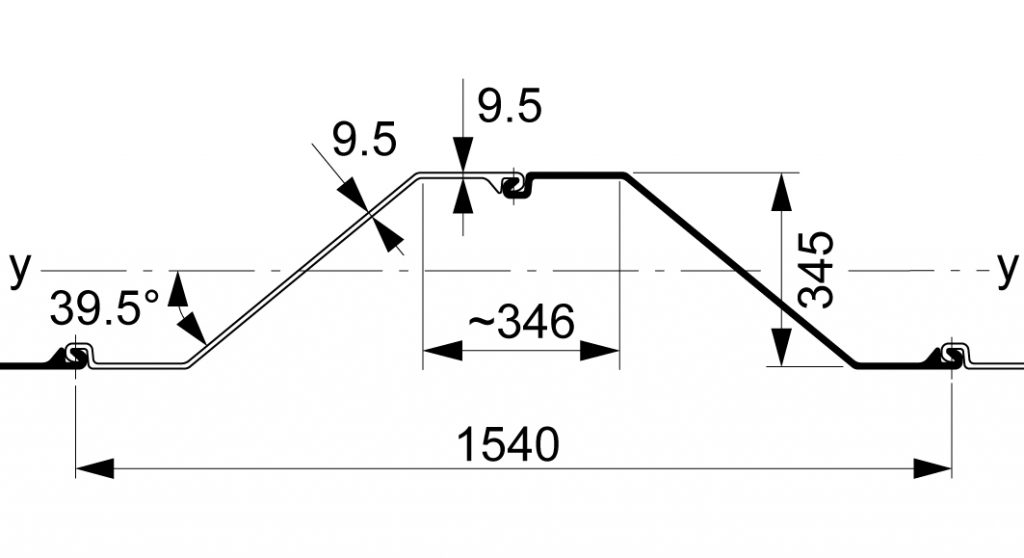

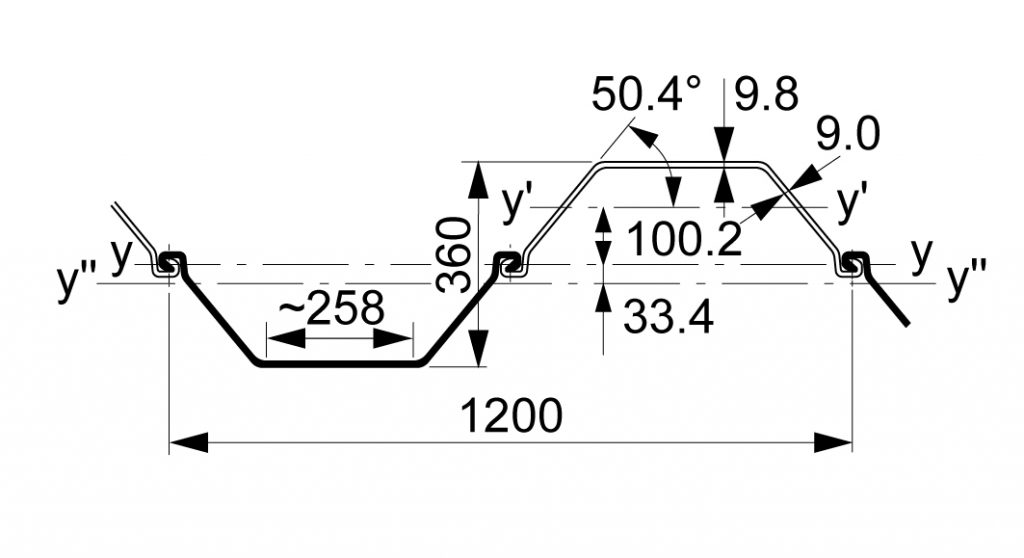

Segments with indented profiles troughs interlock to form a wall with alternating indents and outdents. Z profiles with their optimum distribution of material are the most efficient sheet piling sections available for bending strength. The pile transfers pressure from the high side of the wall to the soil in front of the wall. Structures include basements underground carparks and abutments for bridges including integral bridges.

With the interlocks located on the outer fibers of the wall rather than at the center line as is the case with arch or u profile sheet piling sections the wall designer is assured of the published. Product range sheet pile sections status. Hsp hoesch spundwand und profil gmbh is one of the leading suppliers of hot rolled steel piles and shipbuild. In the uk three profiles designated as u z and straight web are available.

The troughs increase resistance to bending.