Sheet Metal Flange Height

Thick ness min bend radii min.

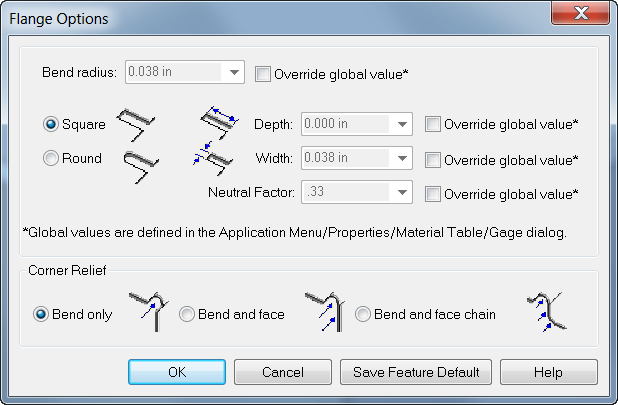

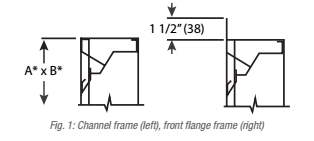

Sheet metal flange height. Design for manufacturability sheet metal guidelines bends for the ease of manufacturing multiple bends on the same plane should occur in the same direction. Height of curved flange min. Bends in sheet metal are manufactured using sheet metal brakes. Mild sheet metal low carbon monel sheets annealed.

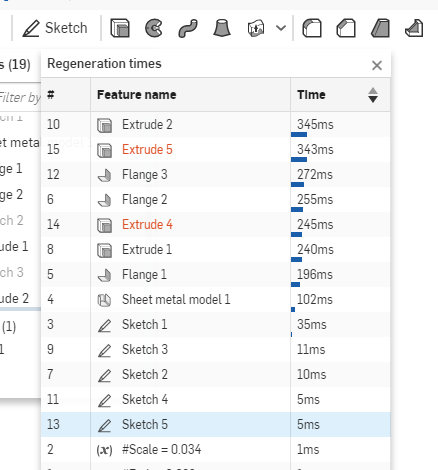

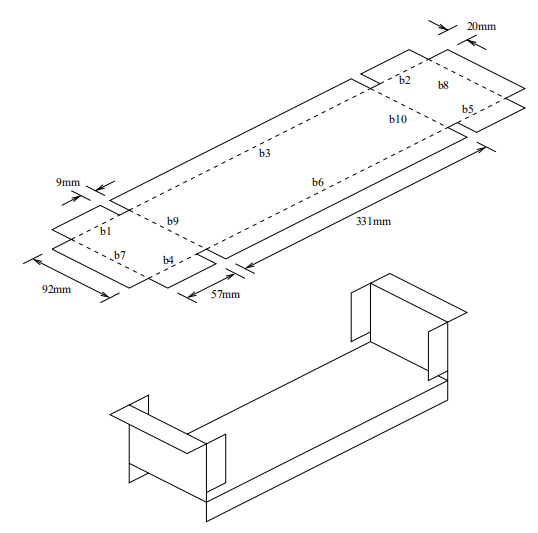

Columnist gerald davis continues a discussion of 3 d cad and precision sheet metal manufacturing in part iii of a four part series focusing on design guidelines for sheet metal. Metal thickness 2024 0 aluminum formed before heat treatment. It shall be equal to three times of sheet thickness plus bend radius. Sheet metal parts with a minimum of 0 9mm to 20mm in thickness can be manufactured.

0 304mm from top of sheet to top of form and recommend an offset of 0 030 in. Determine your minimum bend by measuring the distance from your closest feature i e. However for typical parts meant to be cost effective and easily produced the following tips should be useful. Bends are the most typical feature of sheet metal parts and can be formed by a variety of methods and machines which negate the absolute need for some of the below tips.

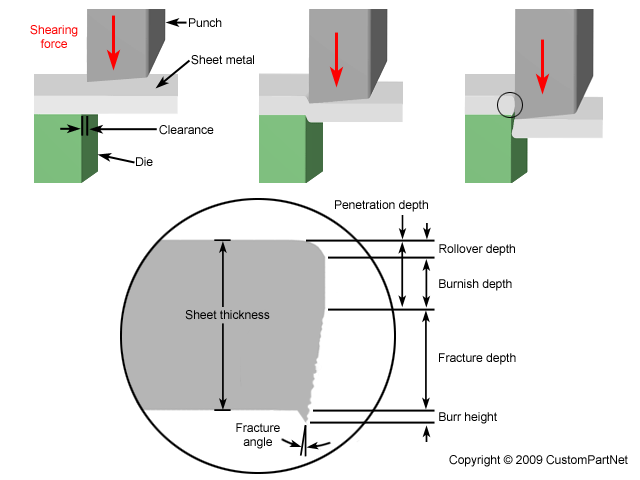

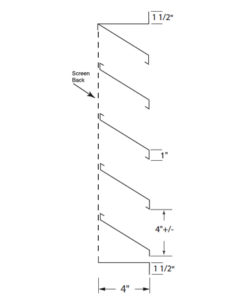

Too small a flange height that is the use of a bending die is also not conducive to forming generally the height of the flange is l 3t including the wall thickness. When designing parts for laser cutting one should not make holes smaller than the thickness of the material. Step processing method some of the lower profile sheet metal z shaped steps are bent and the processing manufacturers often use simple molds to machine on punch presses or. Minimum sheet metal flange bend length is required to avoid cracks in the bending area.

We are here to help. Offsets are used to create z shaped profiles in sheet metal parts. In low carbon steel sheet metal the minimum radius of a bend should be one half the material thickness or 0 80 mm. In low carbon steel sheet metal the minimum radius of a bend should be one half the material thickness or 0 80 mm 0 03 inch whichever is larger counterbores.

Previous editions covered economic order quantity in batch production and the accuracy of things made from rolled sheet stock. We offset height tolerance at 0 012 in. Next month concludes with the pros and cons of hems jogs and forming tools. Choose a bend radius that matches your minimum bend.

If you have any questions or want to discuss your design contact us. Thick ness min bend radii. Avoid large sheet metal parts with small bent flanges. The minumum flange length is based on the die used to bend.

A cutout or the edge of your flange to your bend. Height of curved flange min. The minimum distance between two counterbores is eight times the material thickness.