Sheet Metal Forming Simulation Abaqus

Abaqus routine and advanced simulation linear and nonlinear static and dynamic thermal electrical acoustics.

Sheet metal forming simulation abaqus. Therefore simulating these processes numerically can be a difficult task. The step time was one second. Abaqus explicit is used for this analysis. Metal forming with abaqus abaqus 2018.

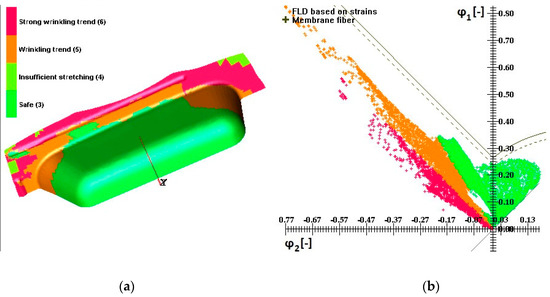

Particularly on the blank part where there is a dissimilar mesh. Metal forming with abaqus 2017. Course objectives in this course you will learn practical modeling skills and techniques for. In this blog i ll give an example of this effect showing that we can model it with abaqus.

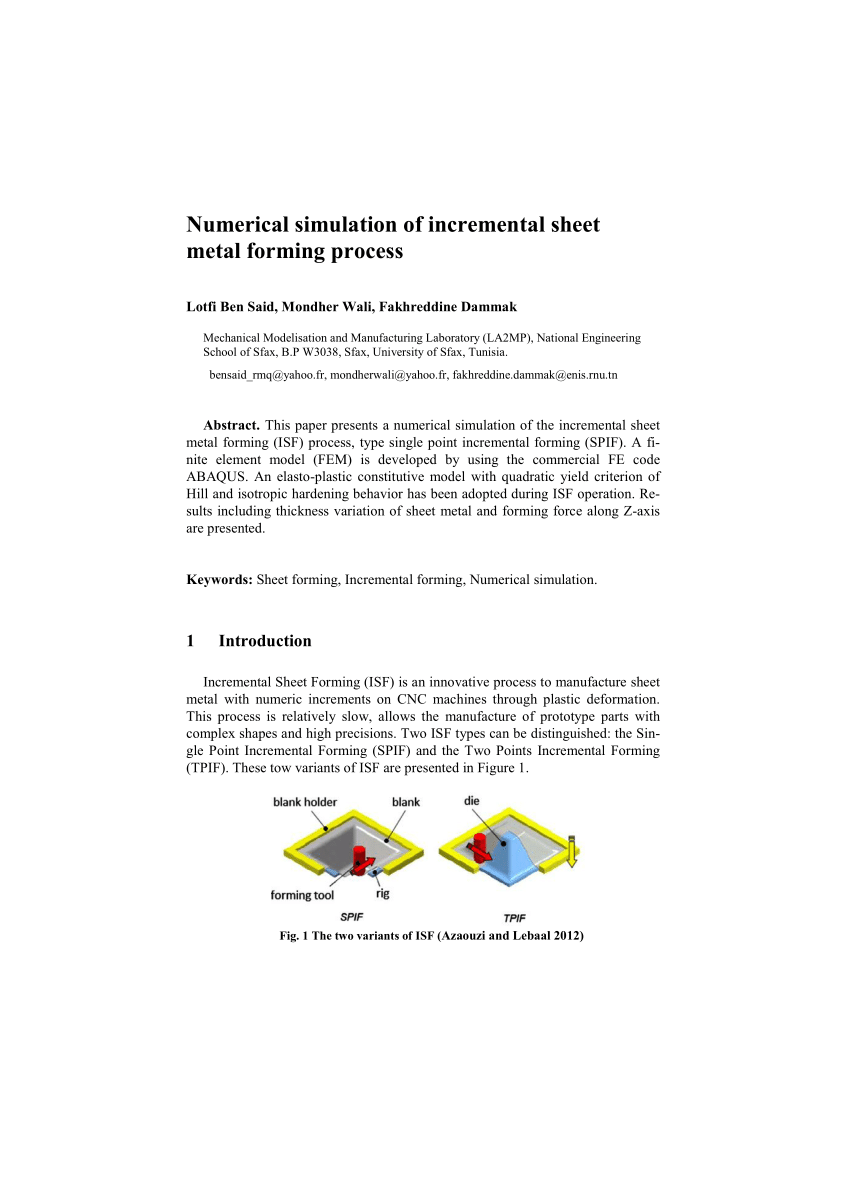

Only a quarter of the geometry is simulated for reasons of symmetry. As an example to test the ductile failure idea the finite element simulation of a metal forming process was made in abaqus. Finally some proposals to overcome these defects are presented. I am doing a metal forming simulation in abaqus and i want to create a mesh similar to the one in the attached image.

Simulations were used to optimize tooling. Although the simulation of this kind of problem is successful some inherent defects of abaqus are found. Abaqus routine and advanced simulation linear and nonlinear static and dynamic thermal electrical acoustics. The shape of the blank the sheet metal is shown.

The geometry of the forming dies is shown below. Manufacturing simulation sheet metal bending abaqus cae implicit standard duration. The sheet metal passes through all the rollers and obtains its final shape. However numerical simulations of forming processes present advantages that outweigh the difficulties.

Abaqus sheet metal forming instability prediction capability simulia june 2008 provided extremely valuable insights after an unacceptable rate of sheet metal fractures was observed during the bottle s initial prototyping process. Webinar on tribology in sheet metal forming simulations triboform r3 duration. Course objectives in this course you will learn practical modeling skills and techniques for. Once the sheet metal is in contact with the rotating rollers it will be pushed forward by them and it s deformation is determined by the contact with the rollers.